Ever stared at a 6-point and a 12-point socket, trying to figure out the real difference? You're not alone. This choice, which seems small, can have a big impact on a mechanic's efficiency and the quality of a repair job. Hello, I'm Allen, and from my experience overseeing 7 production lines here in China, I've learned a lot about what makes a great tool. I want to clear up the confusion about the 6-point vs. 12-point socket debate. This guide is for you, whether you're a procurement officer like Mark Thompson sourcing tools for hardware stores across the USA, or a professional mechanic looking for the best tool for the job. We'll explore which socket to use and when, so you can make informed decisions that prevent stripped bolts and save time.

What Is a Socket and Why Is It a Basic Tool in Every Toolkit?

At its core, a socket is a type of wrench that attaches to a handle, most commonly a ratchet. Its job is simple: to turn a fastener, like a bolt or a nut. But its importance is huge. Imagine trying to perform any kind of automotive repair or assemble furniture without one. It would be nearly impossible. A socket allows you to apply torque to a fastener far more efficiently and with greater control than a traditional wrench. This is why a good socket set is considered a foundational, basic tool for any professional or DIYer.

The magic of the socket is in its design. It fits perfectly over the head of a fastener, allowing you to apply force evenly. This minimizes the risk of damaging the bolt head or your knuckles. When you're sourcing tools, you'll see a huge variety. You have standard sockets, deep sockets for longer bolts, and powerful impact sockets designed for use with air or electric impact wrenches. Sockets are the workhorses of the mechanic's world, used for everything from changing a tire to rebuilding an engine.

In my factory, we produce millions of sockets every year. We know that for our customers in Europe and Australia, the quality of that simple socket is a reflection of their own business. A good socket needs to be made from high-quality material, like Chrome Vanadium (Cr-V) steel, to withstand repeated use and high levels of torque. It's not just a piece of metal; it's a critical component for effective and safe repair work.

The Anatomy of a Socket: What Do "6-Point" and "12-Point" Actually Mean?

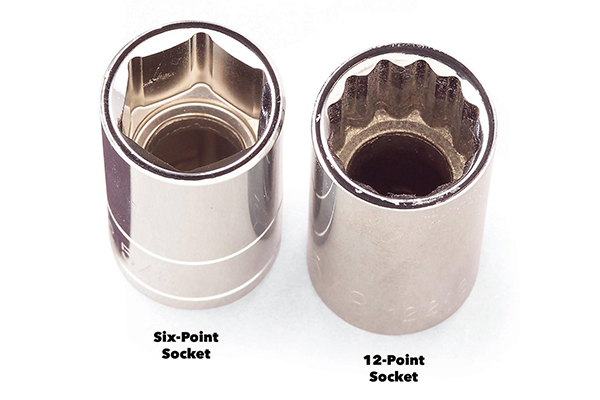

Let's get straight to the main point. The "point" number refers to the number of points, or corners, inside the socket's opening. It’s all about the internal geometry of the socket.

- A 6-point socket has a hexagonal shape inside, with six points. It's designed to fit perfectly onto a standard hexagonal (6-sided) bolt or nut.

- A 12-point socket has a double hexagon shape, giving it twelve points inside.

The difference seems minor, but it fundamentally changes how the socket interacts with a fastener. A 6-point socket makes contact with the large, flat sides of a bolt head. A 12-point socket, due to its design, makes contact closer to the corners of the bolt head. This single difference in contact points dictates the best use case for each socket.

Here’s a simple breakdown to visualize the difference:

| Feature | 6-Point Socket | 12-Point Socket |

|---|---|---|

| Internal Shape | Single Hexagon | Double Hexagon |

| Number of Points | 6 | 12 |

| Contact Area | Flat sides of the fastener | Corners of the fastener |

| Primary Use | High-torque applications | General use, tight spaces |

Understanding this basic anatomy is the first step in choosing the right tool. When we manufacture these sockets, the precision of these points is critical. Even a slight imperfection can lead to slippage and a damaged fastener, which is why rigorous quality control is so important.

When Should You Use a 6-Point Socket for Maximum Grip?

You should reach for a 6-point socket whenever you need to apply a significant amount of force or when you're working with a stubborn, rusted, or slightly damaged fastener. The reason is simple: grip. Because a 6-point socket makes contact with the thickest, flattest parts of a nut or bolt, it provides a superior grip. This design spreads the turning force over a larger surface area.

Think of it like trying to open a jar. If you use just your fingertips (like a 12-point socket on the corners), you might slip. But if you use your whole palm (like a 6-point socket on the flats), you get a much better grip and more turning power. This is why a 6-point socket is less likely to slip off the fastener, even under extreme pressure from a long breaker bar.

For any heavy-duty job, especially in automotive repair where bolts can be seized by rust and heat, the 6-point socket is the professional's choice. It’s your best defense against "rounding" the corners of a bolt head, a frustrating problem that can turn a simple job into a major headache. If you're trying to loosen a tough lug nut or a suspension bolt, a 6-point socket gives you the confidence that the tool will hold firm.

Why Do 6-Point Sockets Offer Superior Durability and Strength?

The strength of a 6-point socket comes from its physical design. The walls of a 6-point socket are inherently thicker than those of a 12-point socket of the same external size. Look inside the two sockets side-by-side. You'll see that the hexagonal shape of the 6-point socket allows for more metal between the points. More metal means more strength and greater durability.

These thicker walls are crucial when dealing with high torque. When you're pulling hard on a wrench or using an impact gun, you're putting immense stress on the socket. The thicker walls of the 6-point design resist flexing and are less likely to crack or fail under that pressure. This is a key reason why nearly all impact sockets—the ones designed for the extreme forces of power tools—are 6-point.

As a manufacturer, this is a critical design consideration for us. When a customer like Mark orders our high-quality sockets offer, he needs to trust that they will stand up to professional use. The geometry of a 6-point socket is simply more robust. While both sockets are made from hardened steel, the 6-point design maximizes the material's strength, ensuring it can handle the toughest jobs without failing the mechanic who relies on it.

Are 12-Point Sockets More Versatile for Different Types of Fasteners?

Yes, one of the key selling points of a 12-point socket is its versatility. While the most common fastener head is the standard hex (6-sided), you will occasionally encounter other types. A 12-point socket has the unique advantage of being able to fit on more than just standard hex heads.

Specifically, a 12-point socket can be used on:

- Standard 6-point (hex) fasteners

- 12-point fasteners (often found in automotive and aerospace applications, especially on engine components)

- Square fasteners (4-sided bolts and nuts)

This flexibility can be a lifesaver. Instead of needing a separate tool for a square bolt, a mechanic might be able to use a 12-point socket from their standard set. For procurement officers, stocking versatile 12-point socket options means offering a product that can solve more problems for the end-user. This makes a 12-point socket a very valuable and versatile part of any toolkit.

However, this versatility comes with a trade-off. While it can fit a square nut, the contact and grip are not as secure as a dedicated 8-point socket would be. Its main advantage remains its ability to work with both the common 6-point bolt and the more specialized 12-point bolts. For general-purpose repair and maintenance, this versatility makes the 12-point socket an extremely popular choice.

How Does a 12-Point Socket Help with Hard-to-Reach Fasteners?

The biggest advantage of a 12-point socket is its performance in tight, confined spaces. This is all about the angle of engagement. A 12-point socket has its points spaced every 30 degrees (360° / 12 points = 30°). A 6-point socket has its points spaced every 60 degrees (360° / 6 points = 60°).

What does this mean in the real world? It means a 12-point socket can engage with a fastener with much less swing room for your ratchet handle. You only need to swing the ratchet handle 30 degrees to get a new "bite" on the fastener. A 6-point socket requires you to swing it a full 60 degrees. If you are working in a cramped engine bay where your range of motion is severely limited, that 30-degree difference is huge. It can be the difference between being able to tighten or loosen a bolt and not being able to move it at all.

This ability to work with hard-to-reach fasteners is why many mechanics love their 12-point sockets. When there is not enough space to get a full swing of the wrench, the 12-point socket allows them to make small, incremental turns to get the job done. It offers more engagement opportunities, making it faster and more convenient for many routine tasks where high torque isn't the primary concern.

What is the Risk of Rounding a Bolt, and Which Socket is Safer?

"Rounding" a bolt or nut is when the corners of the fastener head get stripped and worn down, making it impossible for a socket to get a good grip. It's a frustrating and time-consuming problem. The risk of this happening is directly related to the type of socket you use.

A 6-point socket is significantly safer and less likely to round a fastener. As we discussed, it applies force to the strong, flat sides of the bolt head. This distributes the pressure evenly and away from the weaker corners. The socket essentially "hugs" the fastener, providing a secure grip that prevents slippage.

On the other hand, a 12-point socket is more likely to round a fastener, especially if the bolt is tight or has any pre-existing wear. Because its points make contact very close to the corners of the bolt head, the turning force is concentrated on a smaller, more vulnerable area. If you apply a large amount of torque, that force can cause the corners of the fastener to deform or "round off." Once the corners are gone, the socket will just slip and spin, and you'll be reaching for a bolt extractor. This is the critical trade-off: the 12-point socket gives you better access in tight spaces, but it does so at a higher risk of damaging the fastener.

Can You Use a 12-Point Wrench on a 6-Point Bolt?

Yes, absolutely. This is one of the most common uses for a 12-point socket or wrench. A 12-point tool is designed to fit perfectly onto a standard 6-point (hexagonal) fastener. This compatibility is a major reason for its popularity. In fact, many standard combination wrench sets feature a 12-point box end for its convenience and ease of use in tight spots.

The reverse, however, is not true. You cannot use a 6-point socket on a 12-point fastener. The hexagonal shape of the 6-point socket simply will not fit over the star-like shape of a 12-point bolt head. This is an important distinction to remember.

So, to summarize the compatibility:

- 12-Point Tool on 6-Point Fastener: Yes, works perfectly.

- 12-Point Tool on 12-Point Fastener: Yes, this is what it's also designed for.

- 6-Point Tool on 6-Point Fastener: Yes, provides the best and most secure fit.

- 6-Point Tool on 12-Point Fastener: No, it will not fit.

For a procurement professional like Mark, this means that stocking a comprehensive 218 Pieces Tool Set that includes both 6-point and 12-point sockets is the best way to serve the needs of a diverse customer base.

High-Torque Showdown: Which Socket is the Champion for Tough Jobs?

When it comes to high torque applications, there is a clear winner: the 6-point socket. This isn't even a debate among professional mechanics. Every aspect of its design is optimized for applying maximum force without failure or slippage.

The combination of its thicker walls and the way it grips the flat sides of a fastener gives it superior strength. When you need to loosen a bolt that has been torqued to hundreds of foot-pounds, or one that is seized with rust, the 6-point socket is the only reliable choice. Using a 12-point socket in these situations dramatically increases the risk of two things: breaking the socket itself or, more likely, rounding the corners of the bolt head. Applying higher torque with a 12-point tool focuses all that pressure on the delicate corners of the fastener, which is a recipe for disaster.

This is why, in our factory, specialized impact sockets designed for use with high-powered tools are almost exclusively made in a 6-point configuration. They are built to withstand the punishing, repeated hammering action of an impact wrench, and the 6-point design is the only one that can reliably transfer that immense torque without damaging the fastener or the tool. When strength is the priority, 6-point is king.

As a B2B Buyer, Which Sockets Should You Stock? A Guide for You

So, Mark, after all this information, what's the bottom line for a buyer like you? The answer isn't to choose one over the other. The answer is to recognize that both 6-point and 12-point sockets are essential tools that serve different purposes. A professional's toolkit is incomplete without both.

Your customers—the hardware retailers, construction companies, and automotive workshops—serve professionals who face different challenges every day. You need to provide them with the right solutions. Here's my recommendation based on what we see in the market:

- Stock a Strong Core of 6-Point Sockets: These are the workhorses. Your customers will rely on them for heavy-duty tasks where torque and reliability are paramount. Ensure you offer a full range of sizes in high-quality 6-point socket sets. Emphasize their durability and grip for tough jobs. This is your high-strength, high-reliability offering.

- Offer 12-Point Sockets for Versatility and Access: These are the convenience tools. They are perfect for general-purpose work and are invaluable for working in tight spaces. Your customers will appreciate the speed and flexibility they offer for routine maintenance and assembly.

- Provide Complete Tool Kits: The best solution for many buyers is a comprehensive tool kit that includes a mix of both 6-point and 12-point sockets, along with ratchets, extension bars, and other accessories. This gives the end-user the best of both worlds and represents a high-value purchase.

- Don't Forget Impact Sockets: For customers in the automotive and heavy machinery sectors, a dedicated line of 6-point impact sockets is non-negotiable. These are a specialty item that signals you understand the needs of serious professionals.

By offering a well-rounded selection, you position yourself as a knowledgeable and reliable supplier who understands the practical needs of the people using the tools. You're not just selling sockets; you're selling solutions to problems.

Key Takeaways to Remember

- 6-Point Sockets for Strength: Use a 6-point socket for high-torque applications, or on stubborn or slightly damaged bolts, to prevent rounding the fastener. Its thicker walls and superior grip make it the stronger, more reliable choice.

- 12-Point Sockets for Access: Use a 12-point socket for general-purpose work and especially in tight, confined spaces where you have limited room to swing a wrench. Its design allows it to engage a fastener with half the swing arc of a 6-point.

- Both are Essential: A complete and professional toolkit needs both 6-point and 12-point sockets to handle the wide variety of jobs a mechanic or technician will face.

- Quality Matters Most: Regardless of the point count, the durability and performance of a socket depend on the quality of the steel it's made from and the precision of the manufacturing process. Always source from a supplier you can trust.

Post time: 07-23-2025