Hello, my name is Allen. For decades, my factory has been the engine behind countless tool brands you see across the United States, Europe, and Australia. I've had the pleasure of working with sharp, decisive business owners like Mark Thompson, who are responsible for procuring high-quality tool storage and tool kits. Mark knows how to sell, but he relies on experts like me to understand the technical details. One of the most common, and most important, conversations we have is about the humble socket. It might seem like a simple piece of metal, but choosing the right type of socket is critical for safety, efficiency, and the bottom line. This guide will break down everything you need to know, from the difference between an impact socket and a regular socket to why the length of a deep socket matters, ensuring you make the best purchasing decisions for your customers.

What is a Socket and Why is it so Fundamental?

At its core, a socket is a type of wrench head that fits over a fastener (like a nut or bolt) to tighten or loosen it. Unlike a traditional wrench that has a built-in handle, a socket is a modular component. It attaches to a handle, most commonly a ratchet, which allows for continuous rotation without having to lift and reset the tool. This mechanism makes working with nuts and bolts incredibly fast and efficient. Every good socket set is a cornerstone of a mechanic's or handyman's toolkit.

The anatomy of a socket is simple but brilliant. One end, the socket head, is shaped to grip a specific size and type of fastener—usually a hexagonal one. The other end has a square hole, the drive hole, that connects to the ratchet or another driver like a breaker bar or extension bar. This simple design is what makes the socket system so versatile. You can have one ratchet and a whole range of sockets in different sizes, both metric and imperial, allowing you to tackle nearly any job involving a nut or bolt.

Regular Chrome Socket vs. Impact Socket: Is it Just the Color?

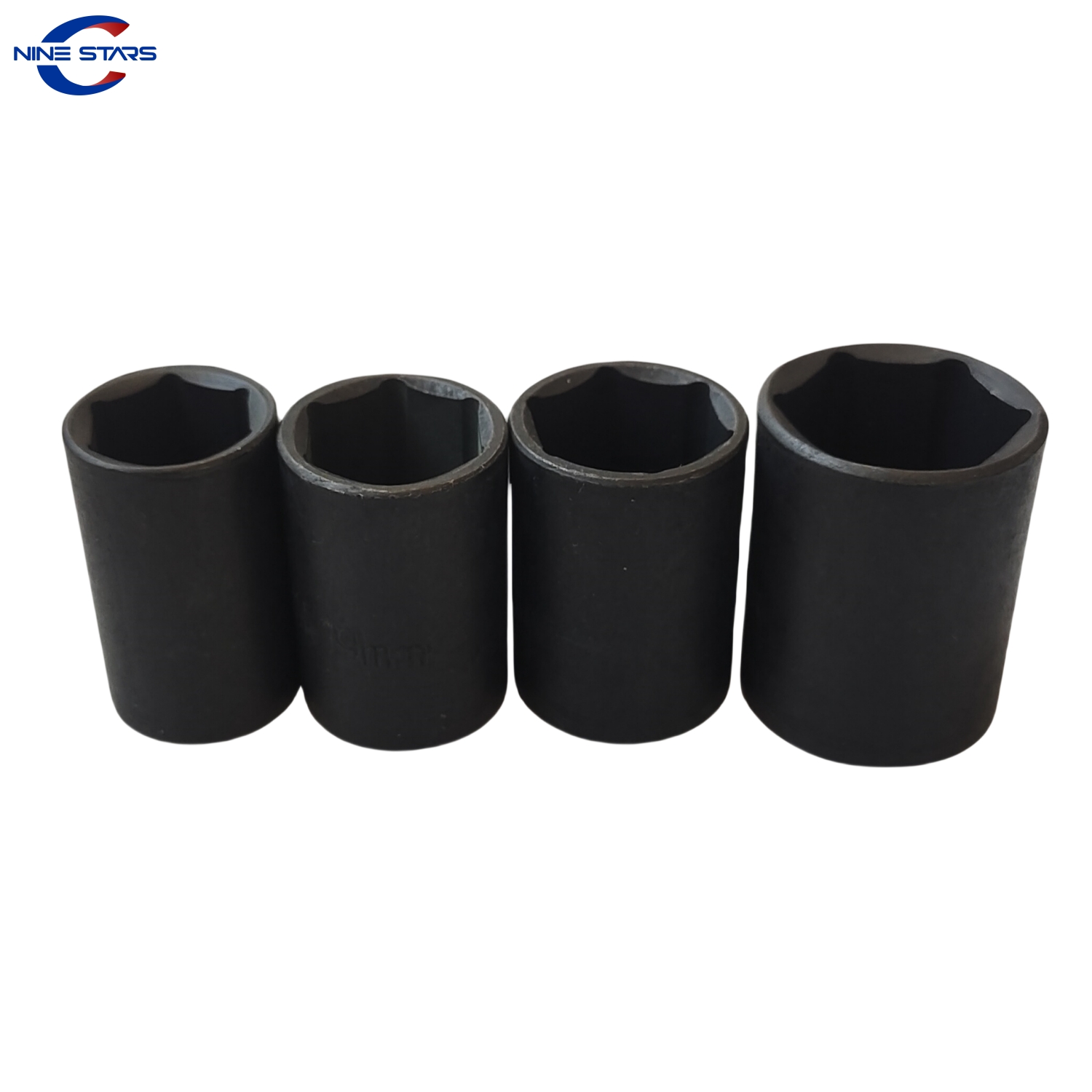

This is one of the most critical distinctions to understand, and it's a matter of safety and performance, not just aesthetics. While a regular socket is usually shiny and chrome-plated and an impact socket is typically black, the difference runs much deeper. It all comes down to the metal they are made from and how they are engineered to handle force, or torque.

A regular socket, also known as a hand socket or chrome socket, is typically made from chrome vanadium steel. This alloy is very hard, which allows the socket walls to be thinner. Thinner walls are great for fitting into tight spaces. The chrome plating provides a sleek look and makes the socket easy to clean and non-corrosive. These sockets are designed for use with a hand tool like a ratchet or a breaker bar, where the force is applied smoothly and predictably by a person.

An impact socket, on the other hand, is built for violence. It's designed to be used with an impact wrench or impact driver, which deliver powerful, rapid rotational bursts of force. To handle this, impact sockets are constructed from a softer, more ductile metal like chrome molybdenum steel (also known as chromoly). This steel is less brittle and can flex and absorb the shock of the impacts without shattering. The black oxide finish on an impact socket isn't just for looks; it provides corrosion resistance without the risk of the chrome plating flaking off and getting into machinery, which is a major concern in automotive and industrial settings.

| Feature | Regular Socket (Chrome) | Impact Socket (Black Oxide) |

|---|---|---|

| Material | Chrome Vanadium Steel | Chrome Molybdenum Steel |

| Hardness | Very Hard & Brittle | Softer & More Ductile |

| Wall Thickness | Thinner | Thicker |

| Intended Tool | Hand Tools (Ratchet, Breaker Bar) | Power Tools (Impact Wrench) |

| Finish | Polished Chrome Plating | Black Oxide Coating |

| Primary Advantage | Fits in tight spaces, easy to clean | Durability, withstands high torque & impact |

Why You Must Never Use a Regular Socket with an Impact Wrench

This is a rule that cannot be broken. Using a regular chrome socket with an impact wrench is incredibly dangerous. I've heard horror stories from my clients' customers about this exact mistake. The extreme, sudden force from an impact wrench will cause the hard, brittle walls of a chrome socket to fail. It won't bend; it will shatter. When it shatters, it sends sharp metal fragments flying at high velocity, which can cause serious injury to the user or anyone nearby.

Conversely, can you use impact sockets on a regular ratchet? Yes, you can. It's perfectly safe, though not always ideal. Because an impact socket has thicker walls, it may not fit into the same tight spaces as a regular socket. It's also more expensive. But in a pinch, an impact socket will work fine with a hand tool. The golden rule is simple: you can use a stronger socket for a weaker job, but never a weaker socket for a stronger job. Every time a business like Mark's orders a tool kit, I make sure they understand this distinction to pass on to their end-users. It's a fundamental part of responsible tool use.

Deep Socket vs. Shallow Socket: When Does Length Really Matter?

The next major distinction you'll find in any socket set is length. Sockets come in two primary lengths: standard socket (or shallow) and deep socket. A standard socket has a shallow depth and is your go-to for most jobs where the nut or bolt is easily accessible and sits close to the surface. They are compact and provide a very direct connection between the ratchet and the fastener.

A deep socket, as the name implies, is much longer. Deep sockets are longer in length for one primary reason: to reach a fastener that is recessed. The classic example is changing spark plugs in a car. The spark plug sits deep inside the engine block, and a standard socket simply can't reach it. The body of the deep socket is long enough to slide over the exposed threads of a long bolt and engage with the nut at its base. They are also essential for tasks like removing lug nuts from a car wheel, where the nut is set inside the rim. Every mechanic's socket set will have a comprehensive set of deep sockets. Having a good collection of both deep socket sets and shallow sockets ensures you're prepared for any situation.

What Are the Different Socket Drive Sizes?

The drive size refers to the size of the square hole on the back of the socket, which determines which ratchet or wrench it fits. There are three common drive size options, each suited for different scales of work:

- 1/4-inch Drive: This is the smallest and most common drive size. It's perfect for precision work in tight areas, like interior car trim, electronics, or small engine repair. The smaller socket and ratchet allow for delicate control and access to hard-to-reach fasteners.

- 3/8-inch Drive: This is arguably the most versatile and widely used drive size. It strikes a perfect balance between the compactness of the 1/4" drive and the strength of the 1/2" drive. A 3/8" drive socket set is the workhorse for most general automotive and home repair tasks. If you are only going to buy one socket set, a 3/8" drive is an excellent choice.

- 1/2-inch Drive: This is the largest of the common sizes and is built for heavy-duty work that requires high torque. It's the preferred drive size for suspension work on cars, large construction fasteners, and any job where you need to use a long breaker bar to loosen fasteners that are rusted or extremely tight. A good impact socket set for car repair will almost always be a 1/2" drive.

6-Point vs. 12-Point Sockets: Which Type of Socket is Better?

When you look at the business end of a socket, you'll notice it has a series of points that form its shape. The two most common configurations are 6-point and 12-point.

A 6-point socket has a hexagonal shape that matches the shape of a standard hex bolt head. This design has a significant advantage: it makes broad contact with the flat sides of the fastener. This excellent contact minimizes the risk of slipping and "rounding off" the corners of a stubborn or damaged bolt. For applying high torque, especially with an impact wrench, a 6-point impact socket is always the superior and safer choice. This is why most impact socket sets are exclusively 6-point.

A 12-point socket has 12 points inside, allowing it to engage with a fastener in more positions. The primary benefit is that you only have to swing the ratchet 30 degrees to get a new grip, versus 60 degrees for a 6-point socket. This makes a 12-point socket very convenient in tight spaces where your range of motion is limited. However, it makes less contact with the fastener head, gripping closer to the corners, which slightly increases the risk of stripping. While useful, they are generally not recommended for high-torque applications.

Are There Other Important Types of Sockets to Know?

While the standard hex socket is the most common, there are several specialty sockets are designed for specific jobs. Understanding these can help you source more comprehensive kits for your customers.

- Spark Plug Sockets: This is a specialized deep socket with a rubber insert inside. The insert is crucial as it gently grips the ceramic insulator of the spark plug, allowing you to safely lift it out of its deep recess in the engine without dropping or damaging it.

- Universal Joint Sockets: These sockets have a built-in pivot or universal joint, allowing you to approach a fastener from an angle. They are invaluable when a direct, straight-on approach with a ratchet and extension bar is impossible. A standalone universal joint socket adapter can also be used with any standard socket.

- Insulated Sockets: For electricians, safety is paramount. An insulated socket is coated with a non-conductive material and is VDE certified for use on live electrical circuits up to 1000 volts. They are a specialty but essential socket for this line of work.

What Makes a Complete and High-Quality Socket Set?

When I consult with a buyer like Mark, he wants to know what separates a cheap, disposable socket set from a professional-grade one that his customers will value. It comes down to a few key factors. First is the material, which we've discussed. Look for chrome vanadium for hand tools and chrome molybdenum for impact tools. Second, the markings on the socket should be clear and easy to read, either stamped or laser-etched, so you can quickly identify the correct size.

A good socket set should also offer a complete range of sizes without skipping common ones. It should include both metric and imperial sizes if it's meant for general use, especially in the US market. The carrying case is also important; it should be durable and hold each socket securely in its place. Finally, a comprehensive set of sockets will include useful accessories like a good quality ratchet, several lengths of extension bar, and a universal joint. These are the details that turn a box of sockets into a functional system.

How Do You Choose the Right Socket Set for Your Needs?

To choose the right socket set, you need to first identify the primary user. For a general homeowner or DIY enthusiast, a 3/8-inch drive socket set with a good mix of shallow and deep sockets in both SAE and metric sizes is perfect. For a professional auto mechanic, the needs are more extensive. They will require multiple drive sizes (1/4", 3/8", and 1/2"), a complete impact socket set (almost certainly 1/2" drive and 6-point), and specialty sockets like spark plug sockets.

When sourcing for retail, offering a tiered range is often the best strategy. A basic "starter" socket set can meet the needs of beginners, while a larger, more comprehensive professional socket set will appeal to serious users. Pay attention to the quality of the accessories. A ratchet with a high tooth count provides a smoother action in tight spaces, and case quality reflects the overall quality of the product. By understanding these nuances, you can provide your customers with a product that not only does the job but also represents a smart, long-lasting investment. It’s about giving them the right socket for the right bolt, every time.

Key Takeaways

- Material Matters Most: Regular sockets are made of hard, brittle chrome vanadium for hand tool use. Impact sockets are made of softer, tougher chrome molybdenum to withstand the force of an impact wrench.

- Safety First: Never use a regular chrome socket on an impact wrench. It can shatter and cause serious injury.

- Length for a Reason: Use a standard socket for general access and a deep socket to reach recessed nuts or fit over long, protruding bolts.

- Choose the Right Drive: 1/4" is for precision, 3/8" is for general-purpose use, and 1/2" is for heavy-duty, high-torque applications.

- 6-Point for Power: 6-point sockets provide a better, more secure grip and are the best choice for high-torque and impact applications to prevent stripping a fastener. 12-point sockets offer easier access in tight quarters.

- A Complete Set is a System: A great socket set includes a full range of sockets, a quality ratchet, and essential accessories like extension bars, all housed in a durable case.

Post time: 09-23-2025